Jeroen Wats tells us more about DANU, the “sustainable” composite material he is working on, with which he is participating in the JEC Composites Innovation Award. Advantages compared to glass and carbon fibers, application in the nautical industry…

Author: Briag Merlet

Making boats with less impact on the environment

Jeroen Wats has a background in ocean racing, before launching the G-Force Yachts brand in 2004. His environmental awareness has now led him to evolve his business to work on a new material. “The more I read about the risk to the environment, the more I wanted to change that. So I created TYNC (The Young Naval Architects) in 2015 to give young naval architects and designers the opportunity to innovate. So we worked on a sustainable composite. The specifications had 4 main points: to be stronger than fiberglass, to be as durable as possible (we are never 100% durable today), to be economically affordable, to have a solution for managing the end of the material’s life” says the entrepreneur.

A recyclable biocomposite without loss of properties

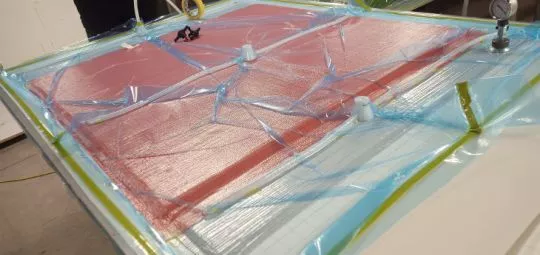

After 2 years of research, Jeroen Wats and his team have filed a patent, with the company Exo Tech, soon validated for the DANU, a durable and reusable composite. The composition remains confidential, but it is a bio-composite. “The working methodology is identical to the current composite. There is no need to relearn the trade or make new molds. Any job site that knows how to infuse can switch to UND. It’s a little more expensive than fiberglass, but it’s stronger so you can use less, and most importantly, it’s upcyclable. Carbon loses 20% of its strength when reused and ends up in landfill. The DANU has no mechanical loss. From a boat made of DANU, one can remake a boat or a wind turbine blade. It is also more flexible than carbon. This can be useful for motor boats for example. On the other hand, you can make an IMOCA, but not break records with it, because of this flexibility. DANU is an answer to fiberglass, but not to everything. It’s already good because there are 250,000 tons of fiberglass buried in Europe every year,” says Jeroen Wats.

Sailboats and powerboats made of durable composite

The first applications of the UND have been around for a short time. Jeroen Wats has joined The Ultimate Boat Company (UBC) shipyard, which builds powerboats for a variety of professional and recreational applications. “The first 2 boats have been built and construction of a 3rd, a RIB, starts in July 2021. Compared to fiberglass, we have gone from a weight of 380 kg to 250 kg with the DANU. This allows us to put the weight where it is useful” explains Jeroen Wats.

A new one-design sailboat model called Olympic 32, designed with the Finot-Conq firm, is scheduled for implementation of the DANU, according to the specifications of World Sailing for the Olympic Games. “We exceed the requirements of World Sailing for 2024 and 2028 on the recyclability of the boat. The project is on hold, pending the IOC decision on the mixed ocean racing event. But the boats will be built in any case, with about ten boats for a strictly one-design fleet. On the other hand, it is not for sale at the moment” concludes the promoter of the DANU.